In the competitive world of home appliance manufacturing, powder coating ovens are the unsung heroes that elevate both the appearance and performance of products. These "magic boxes" apply durable and aesthetically pleasing protective coatings, making home appliances more marketable and long-lasting. This comprehensive guide dives deep into the world of powder coating ovens for home appliances, addressing common concerns and highlighting their benefits.

What Are Powder Coating Ovens for Home Appliances?

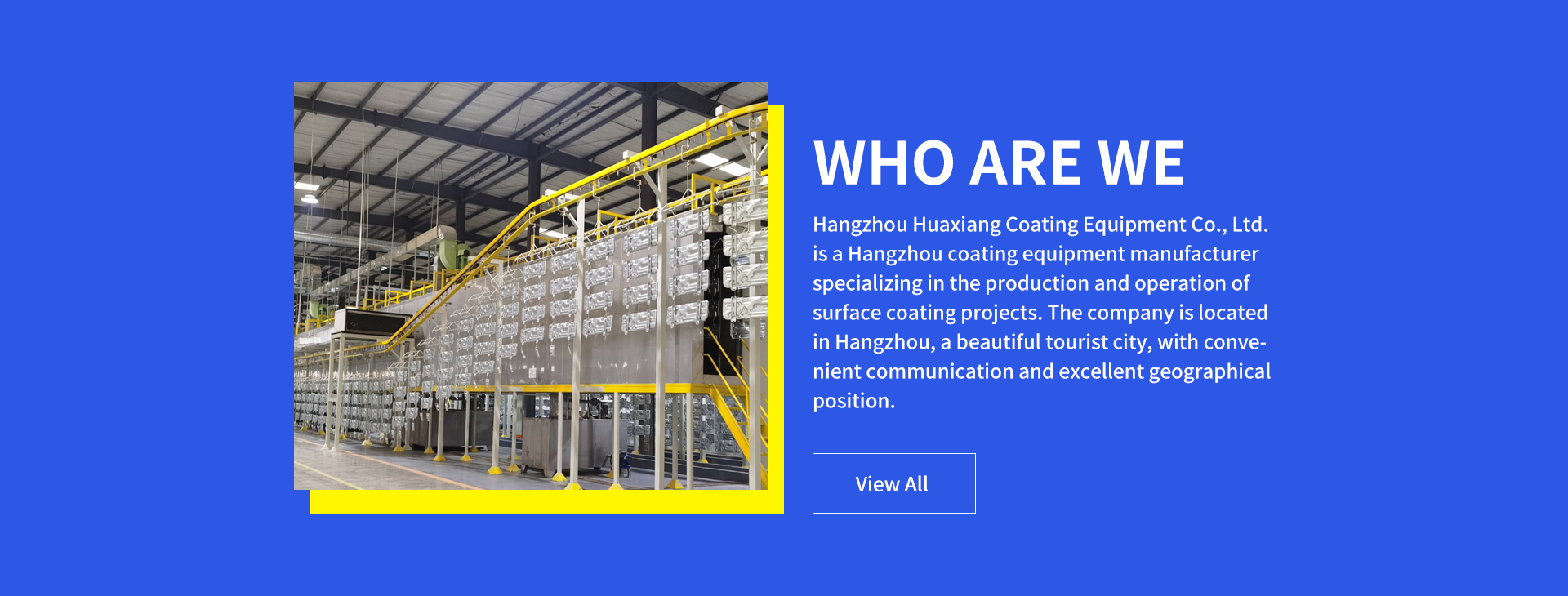

powder coating ovens are specialized equipment designed to cure powder coatings on home appliance components. The process begins with electrostatically charged powder being evenly applied to grounded surfaces. The coated components are then placed into the oven, where precise temperature control ensures the powder melts, levels out, and cures into a solid, durable finish. This not only enhances the visual appeal of home appliances but also improves their resistance to wear, corrosion, and scratches, extending their lifespan.

Types of Powder Coating Ovens for Home Appliances

1. Small-Scale Batch Ovens

Ideal for: Small to medium-sized manufacturers or R&D stages.

Benefits: These ovens offer flexibility, allowing manufacturers to adjust production batches easily. They are perfect for coating small batches of diverse home appliance components.

Example: Niche manufacturers producing specialized small appliances can use these ovens to quickly and cost-effectively coat different product styles.

2. Large-Scale Continuous Ovens

Ideal for: Large-scale home appliance manufacturers.

Benefits: These ovens integrate seamlessly with automated production lines, enabling continuous curing operations. They are essential for high-volume production of appliances like refrigerators and washing machines.

Advantage: They significantly boost production efficiency while maintaining consistent product quality.

Key Advantages of Powder Coating Ovens for Home Appliances

1. Energy Efficiency and Cost Savings

Modern powder coating ovens are designed with advanced heating technologies and superior insulation to minimize heat loss and reduce energy consumption.

Example: High-efficiency infrared heating elements allow for rapid heating and precise temperature control, saving on electricity costs over time.

2. Eco-Friendly and Sustainable

Powder coatings are free from organic solvents, eliminating harmful gas emissions and reducing air pollution.

Bonus: Powder coatings can be recycled, minimizing waste and aligning with green manufacturing practices.

3. Superior Coating Quality

Precise temperature control and optimized oven designs ensure even heating, resulting in uniform and durable coatings.

Result: Enhanced aesthetic appeal and improved protective properties, making products more attractive to consumers.

Frequently Asked Questions About Powder Coating Ovens

1. How to Choose the Right Powder Coating Oven?

Consider your production scale, product types, and budget.

Small-scale production: Opt for small-scale batch ovens for flexibility.

Large-scale production: Invest in large-scale continuous ovens for efficiency.

Tip: Choose reputable brands for better quality and after-sales support.

2. How to Set Temperature and Time for Curing?

Curing parameters depend on the powder coating type and component material.

Typical range: 160–200°C for 15–30 minutes.

Recommendation: Conduct small-batch tests to fine-tune settings.

3. How to Maintain Powder Coating Ovens?

Regularly clean the oven to remove powder residues.

Inspect heating elements, ventilation systems, and control systems for damage.

Ensure proper sealing and follow the manufacturer’s maintenance guidelines.

4. What Are the Safety Precautions?

Install the oven in a well-ventilated area.

Train operators to follow safety protocols.

Avoid opening the oven door during operation to prevent burns.

Ensure proper grounding and check for safety features like over-temperature protection.

5. Can Different Powder Coating Brands Be Used?

Yes, but compatibility testing is essential.

Test new powders for curing performance, adhesion, and appearance quality.

Replace incompatible powders to avoid issues like blistering or peeling.

Conclusion

Powder coating ovens are indispensable in home appliance manufacturing, offering a perfect blend of durability, aesthetics, and efficiency. By understanding their types, advantages, and maintenance requirements, manufacturers can optimize their production processes, reduce costs, and stay ahead in the competitive market. Whether you’re a small-scale producer or a large-scale manufacturer, investing in the right powder coating oven for home appliances can transform your product quality and boost your brand’s reputation.

For more insights on powder coating ovens for home appliances, stay tuned to our blog for expert tips and industry updates!

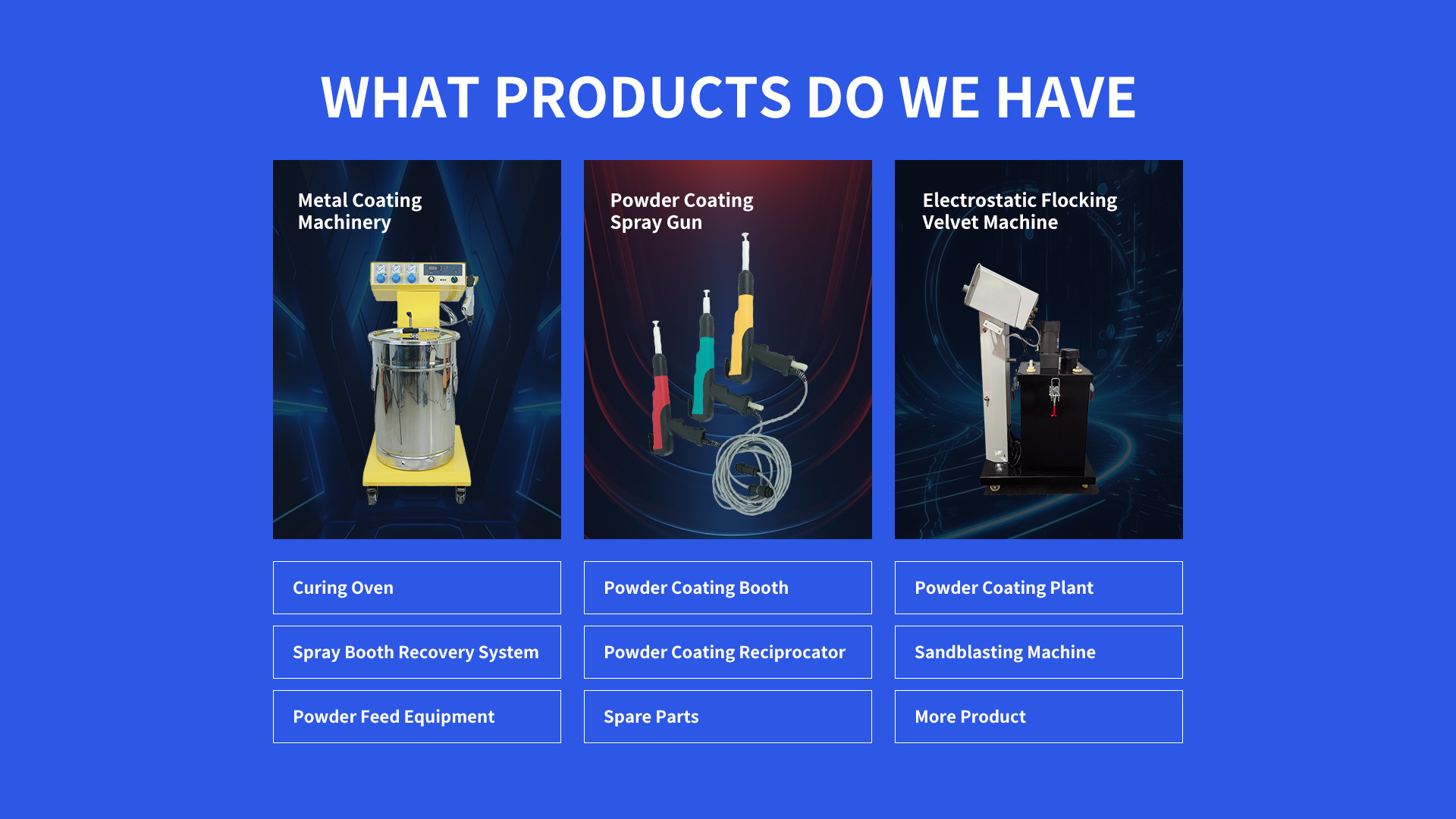

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com